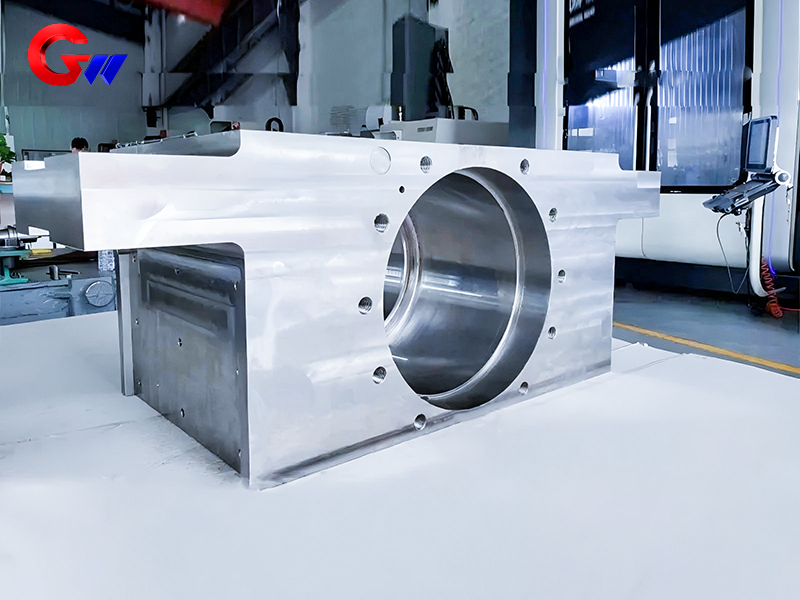

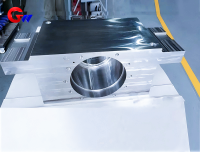

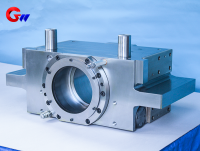

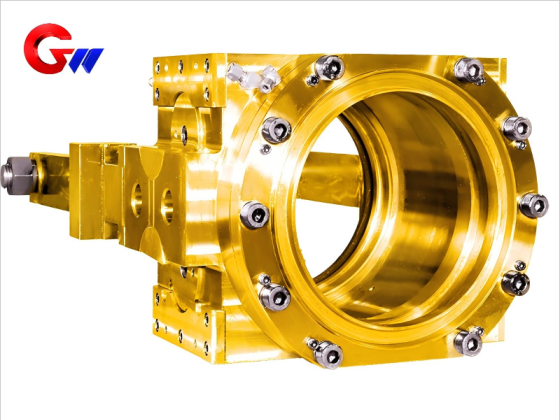

Cold Rolling Mill Machine Of The Transimit Side Work Roller Bearing Block

The Work Roller Bearing Block is a key component in the cold rolling mill, mainly used to support and position the work roll, ensuring the stability and accuracy of the rolling process.

The Transimit Side Work Roller Bearing Block Material:

working roll (forgings):45 steel,40Cr,42CrMo

support roll (castings): zg310-570, zg270-500.

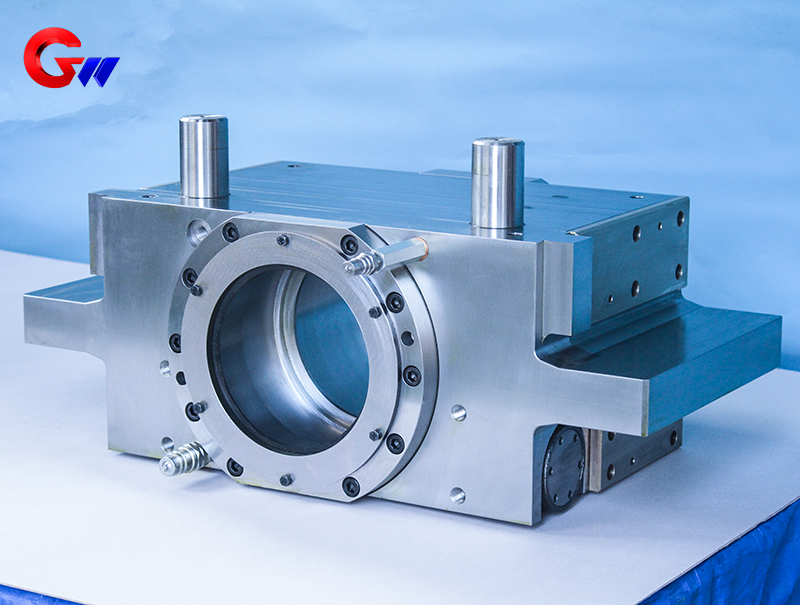

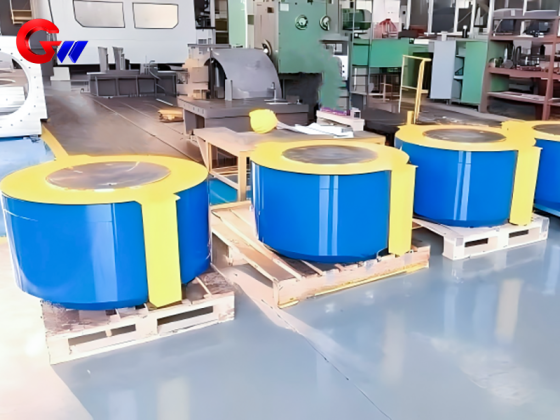

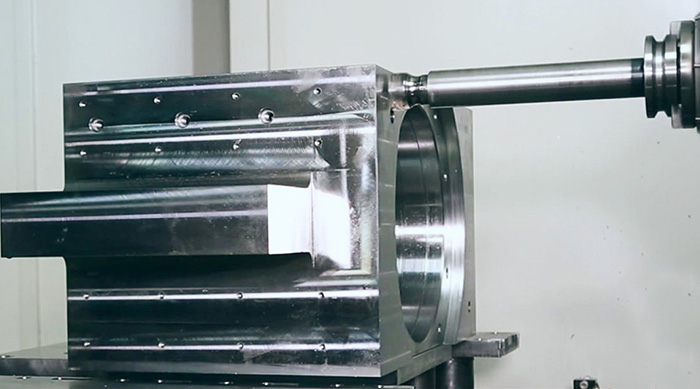

Advantages of GW spool: High-precision intelligent CNC manufacturing equipment, high-tech staff, mature processing system, strict quality inspection process, high-precision inspection instruments, excellent production management process, is the guarantee of high-quality products.

Our company has DMG DMF1800*600 five-axis machining center, horizontal machining center,vertical machining center,gantry machining center and high-precision three-coordinate inspection.Machine 80% of the equipment is CNC machine tools;Powerful equipment, so that we get strong quality assurance in product manufacturing and processing.

In order to better ensure the quality of products, in addition to the normal size inspection, bearing and other precision parts in the three coordinate standard measuring machine instrument for final inspection, detection accuracy up to 2 micron level, to ensure the absolute inspection of various parts size and behavior tolerance inspection basis.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity is 1000 pieces

- Information

Cold Rolling Mill Machine Of The Transimit Side Work Roller Bearing Block

The functional role of Work Roller Bearing Block

Support the work roll to withstand radial and axial forces during the rolling process.

Ensure precise positioning of the work rolls and maintain the thickness and surface quality of the rolled sheet.

Adapt to harsh working conditions such as high speed, heavy load, and high temperature (due to heat generated by rolling friction).

Typical applications

Precision rolling production lines for cold-rolled strip steel, stainless steel, aluminum foil, etc.

Continuous rolling mill (such as acid rolling combined unit), reversible rolling mill and other equipment.

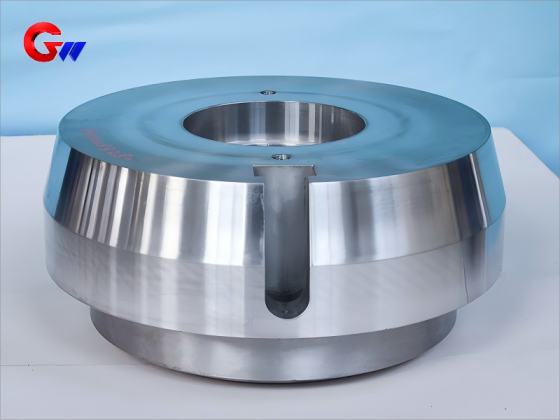

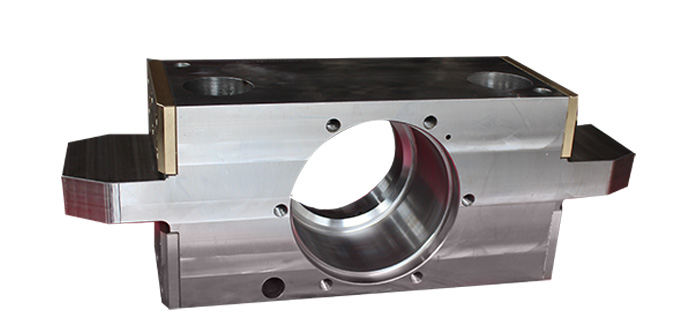

Material selection for Work Roller Bearing Block

Common materials

Cast iron:

HT250/HT300 (gray cast iron): Low cost, good pressure resistance, suitable for small and medium loads.

QT400-18/QT500-7 (ductile iron): It combines strength and toughness, with better fatigue resistance.

Cast steel:

ZG270-500/ZG310-570 (carbon steel castings): High load-bearing capacity, used for heavy-duty rolling mills.

Alloy cast steel (such as ZG35CrMo): Adding elements such as Cr and Mo to enhance wear resistance and high-temperature strength.

Forged steel:

42CrMo/34CrNiMo6: Higher strength obtained through forging process, used for high-end rolling mills.

Selection criteria

Load size (rolling force, impact force).

Wear resistance requirements (friction with the bearing mating surface).

Thermal deformation resistance (local temperature rise during rolling process).

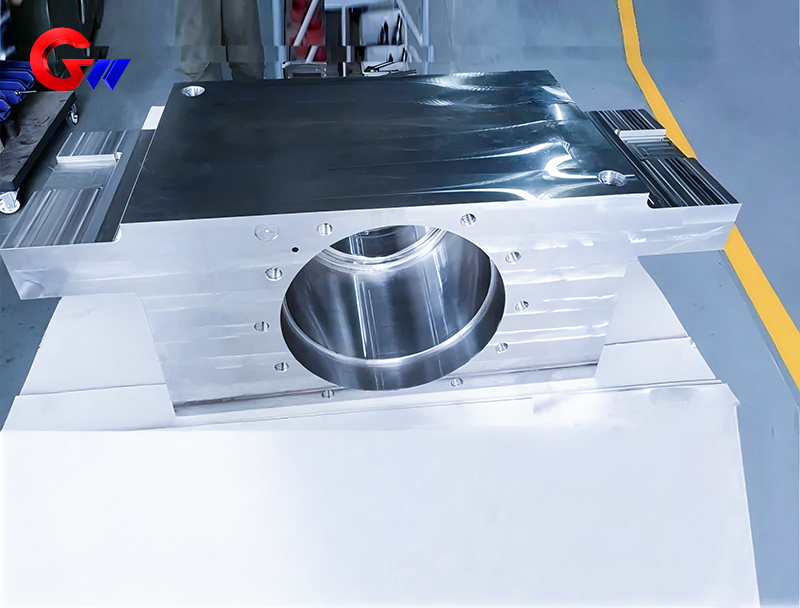

Key processes:

Coaxiality (≤ 0.02mm) and cylindricity control of bearing holes.

The mating surface needs to be ground or scraped to ensure contact accuracy.

heat treatment

Annealing/normalizing: eliminating casting/forging stress.

Quenching and tempering treatment (quenching+high-temperature tempering): improves the comprehensive mechanical properties (such as the hardness HRC28-32 of 42CrMo after quenching and tempering).

Surface hardening (optional): Perform high-frequency quenching or carburizing treatment on the bearing mating surface.

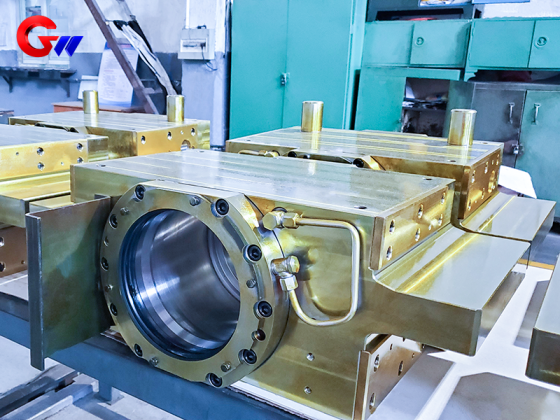

The company has formed a set of mature mechanical processing technology for the production of The Transimit Side Work Roller Bearing Block through the accumulation of long-term experience:

1、 Vertical Machining Center

2、 Horizontal boring machine

3、 Bench-work

4、 Final inspection

Perfect quality management system, effective after-sales service guarantee, so that the company's products won a good reputation.

Start your day off right by reaching out to Luoyang Guangwei Precision Manufacturing Technology Ltd. for any Cold Rolling Mill Machine Of The Transimit Side Work Roller Bearing Block spindle repair needs you may have.

Our technicians are extremely experiences and are some of the best in the industry.

Come see how we can save you downtime and keep you up and running.

guangwei@gwspool.com or +86-379-64593276