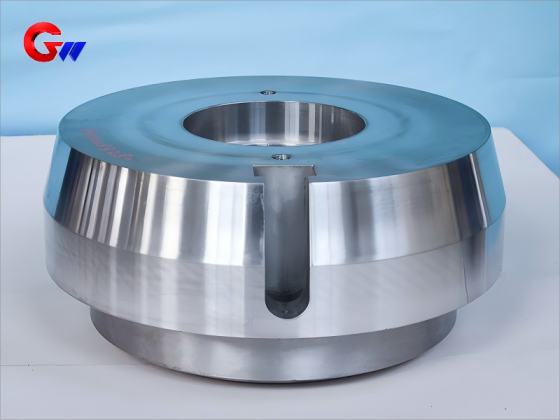

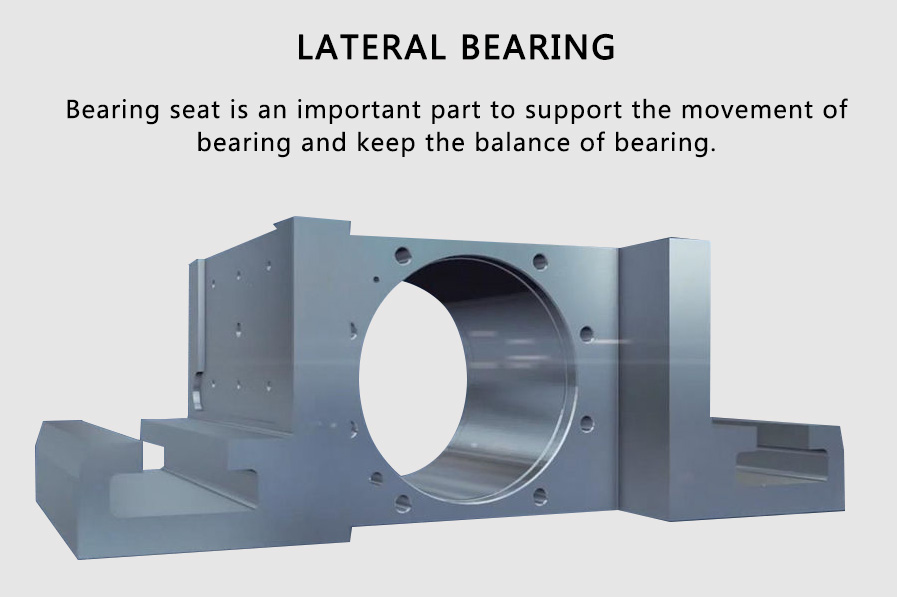

Operation side support roller bearing seat of hot rolling mill

Structural Design and Tolerance of the Operation side support roller bearing seat bearing hole accuracy:

Diameter tolerance: H7 grade (IT7)

Roundness/cylindricity: ≤ 0.02mm

Surface roughness: Ra ≤ 1.6 μ m (bearing mating surface requires Ra ≤ 0.8 μ m)

Installation surface requirements:

Flatness: ≤ 0.05mm/m

Position tolerance of bolt holes: ± 0.1mm

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity is 1000 pieces

- Information

Operation side support roller bearing seat of hot rolling mill

Material and manufacturing standards for Operation side support roller bearing seat

Main material:

Cast steel: ZG270-500 (GB/T 11352) or ZG35CrMo (high-strength working condition)

Forged steel: 42CrMo (ASTM A29) or 35CrNiMo (heavy-duty high-speed rolling mill)

Chemical composition (taking 42CrMo as an example):

Element C Si Mn Cr Mo P ≤ S ≤

Range 0.38~0.45 0.17~0.37 0.50~0.80 0.90~1.20 0.15~0.25 0.025 0.025

Product Information

| Product Name | Material |

| working roll (forgings) | 45 steel、40Cr、42CrMo |

| support roll (castings) | zg310-570、zg270-500 |

Mechanical properties of Operation side support roller bearing seat

Test standard for required values of indicators (42CrMo quenched and tempered state)

Tensile strength (Rm) ≥ 900MPa GB/T 228.1

Yield strength (Rp0.2) ≥ 750MPa GB/T 228.1

Elongation rate (A) ≥ 14% GB/T 228.1

Impact energy (room temperature) ≥ 40J GB/T 229

Hardness 260~320HBW GB/T 231.1

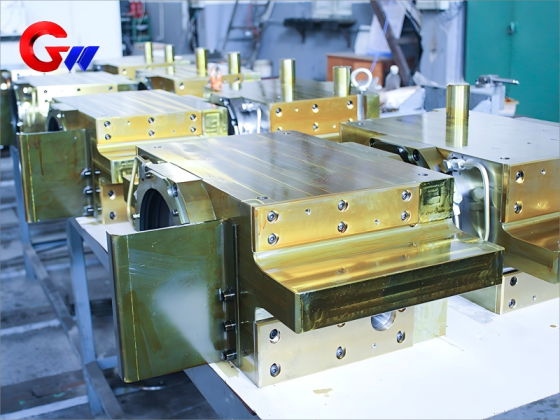

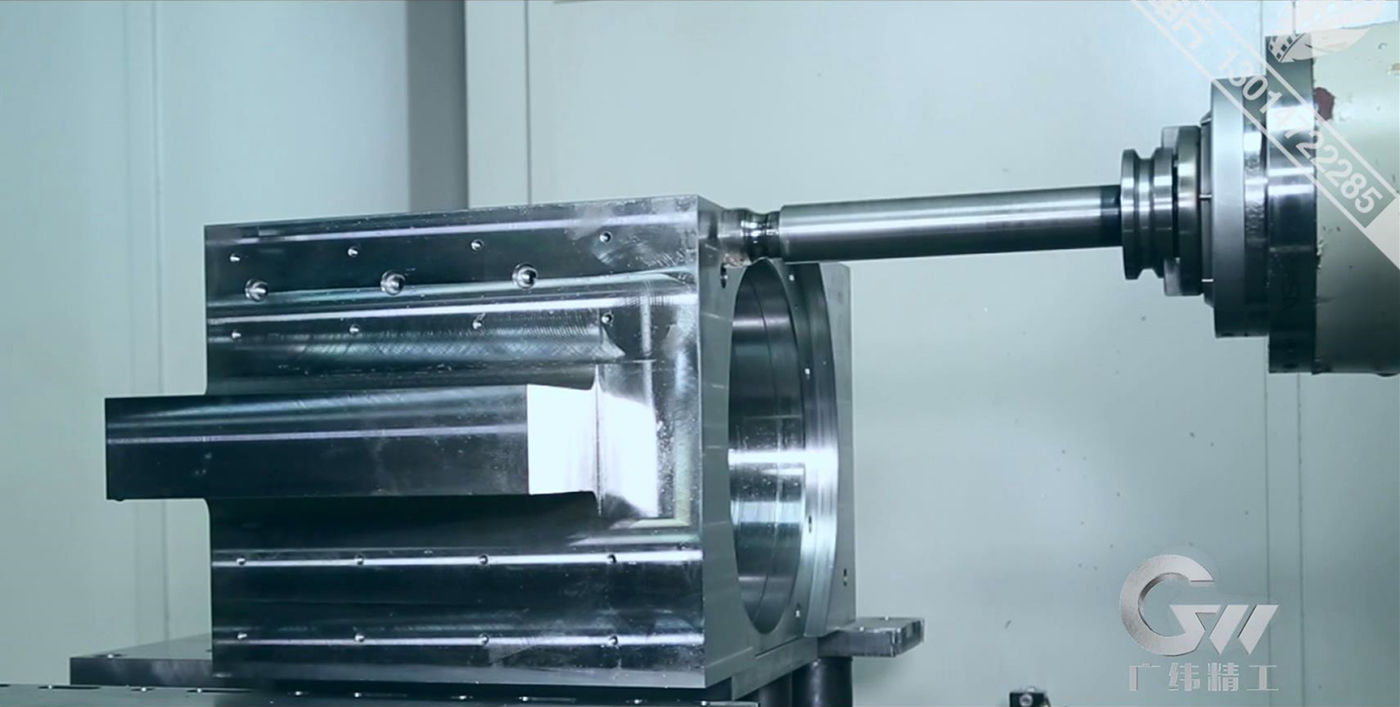

The company has formed a set of mature mechanical processing technology for the production of Operation side support roller bearing seat through the accumulation of long-term experience:

1、 Vertical Machining Center : According to the view shape milling depth 5mm to find the positive belt (each side has room for 1.5-2mm); clean and remove burr sharp edge for inspection. (first piece for inspection)

2、 Horizontal boring machine :It is found that a margin of 1.5 -2 mm is reserved for each surface of the normal belt, and the margin of the groove in the view is 1.5-2 mm; the margin of the hole in the hole is 3-4 mm; the length of each hole is 2-3mm; and the clear edge is used for removing the sharp edge of the burr for inspection. (first piece for inspection)

3、Vertical Machining Center : Finish milling to (non-tolerance fit surface) requirements, milling length to find the right edge depth of 5 mm; boring to the requirements, each side of the residual amount of 1 ≤ 1.5 mm; each hole length to the requirements, and point to the two ends of the hole center hole; to ensure the dimensional tolerance and shape and position tolerance.

4、Horizontal machining center : upper tooling, alignment length and alignment edge are based on the middle hole, and all sides meet the requirements;And point the center hole of each hole on the end face to ensure the tolerance of each dimension and form;Hole deep processing to requirements;Ensure dimensional tolerance;

5、Vertical Machining Center : To the original hole as a benchmark, fine boring hole, to the requirements;Hole processing according to the difference, and then use a rolling knife rolling hole surface;To ensure the tolerance of each hole, a test shall be conducted to keep the allowance of 1mm before machining to the dimension.Clean and remove sharp edges of burrs for inspection.

6、Bench-work:Each thread bottom hole positioning hole to requirements.

7、Bench-work: Other oil hole and screw hole drilling tapping;Clean and remove sharp edges of burrs for inspection. (first piece for inspection)

8、Final inspection : remove sharp edges of burrs by cleaning and send for inspection, and issue inspection list.

In order to better ensure the quality of Operation side support roller bearing seat products, in addition to the normal size inspection, bearing and other precision parts in the three coordinate standard measuring machine instrument for final inspection, detection accuracy up to 2 micron level, to ensure the absolute inspection of various parts size and behavior tolerance inspection basis.

Perfect quality management system, effective after-sales service guarantee, so that the company's roller bearing seat products won a good reputation.

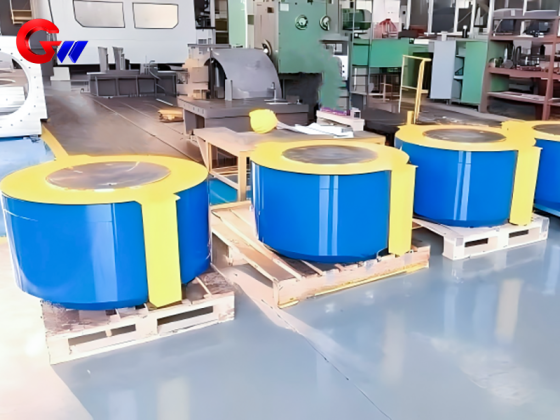

Packaging

We have excellent packaging team and mature packaging technology for roller bearing seat.

The packaging must ensure the safety of roller bearing seat, so that they will not be lost or damaged during storage, transportation and sale.

Packing ensures roller bearing seat cleanliness. Confirm the cleanliness of roller bearing seat product surface before packing.

Our roller bearing seats are widely recognized and trusted by users and can meet continuously changing economic and social needs.

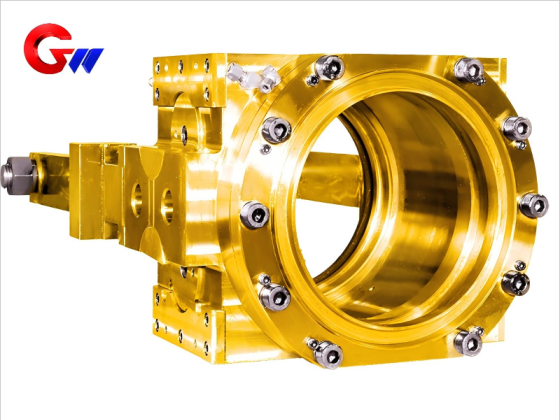

Bearing coordination and lubrication of operate side roller bearing seat

Bearing type adaptation:

Four row tapered roller bearings (such as SKF TQO series) or oil film bearings (MORGOIL)

Matching tolerance:

Bearing outer ring and seat hole: transitional fit (H7/k6)

Bearing inner ring and roller neck: interference fit (H7/S6)

Lubrication requirements:

Thin oil lubrication: ISO VG 220~320 extreme pressure gear oil

Oil air lubrication: pressure 0.2~0.5MPa, flow rate 5~10L/min