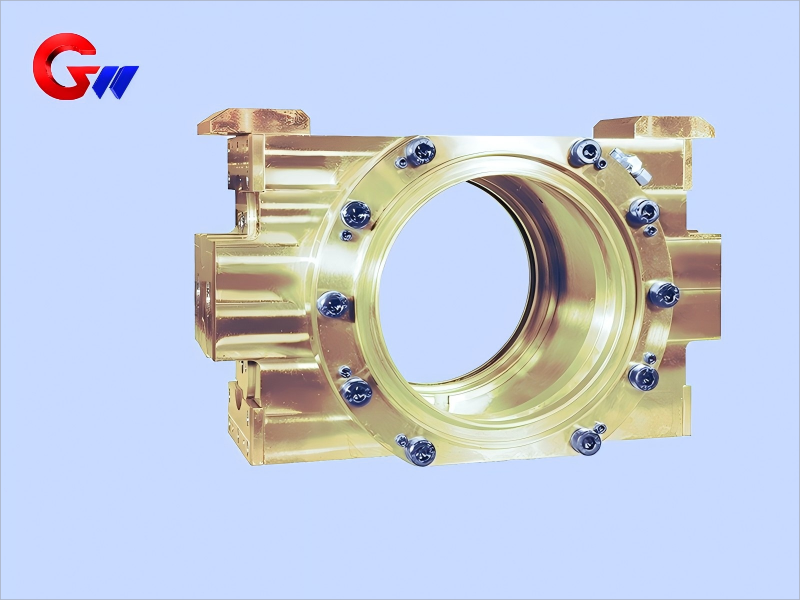

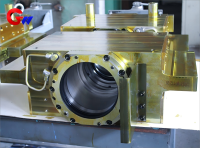

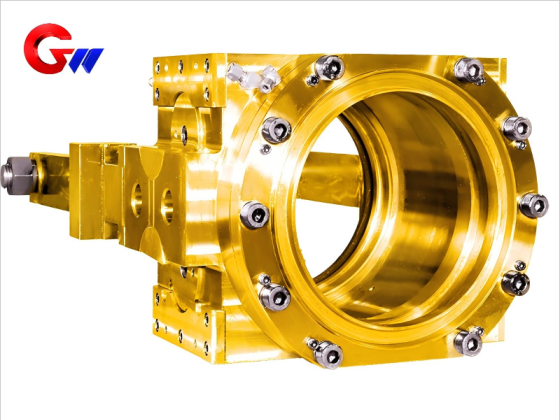

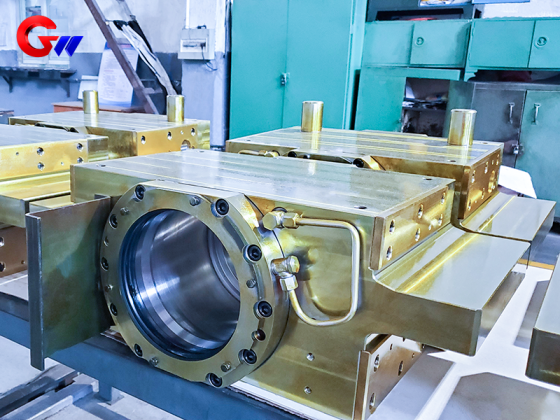

Cold Rolling Mill Machine Of The Operate Side Intermediate Roller Bearing Block

Material and heat treatment of the intermediate roller bearing seat on the operating side of the cold rolling mill

Operate Side Intermediate Roller Bearing Block Body Material:

High strength cast iron (HT300/HT350) or cast steel (ZG310-570), with a tensile strength of ≥ 500MPa.

The wear-resistant lining is made of bronze (ZCuAl10Fe3) or polymer composite material (such as PTFE modified material).

Heat treatment:

Castings require aging treatment (to eliminate internal stress) and high-frequency quenching of critical contact surfaces (hardness HRC45-50).

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Information

Cold Rolling Mill Machine Of The Operate Side Intermediate Roller Bearing Block

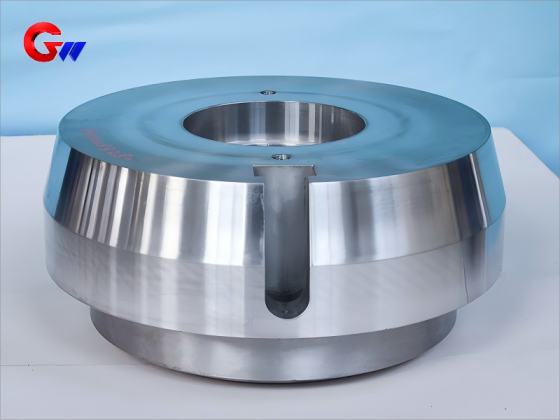

Dimensions and tolerances of Operate Side Intermediate Roller Bearing Block

Bearing installation holes:

According to the type of bearing (such as the TQO series of four row tapered roller bearings), the tolerance is usually H6 (inner hole) or js6 (outer diameter).

Roughness requirement: The Ra of the bearing mating surface is ≤ 0.8 μ m, and the Ra of the non mating surface is ≤ 3.2 μ m.

Positioning accuracy:

The roundness of the inner hole of the bearing seat is ≤ 0.008mm, and the coaxiality is ≤ 0.015mm/500mm.

The fit clearance with the roll neck: 0.05-0.10mm (considering thermal expansion).

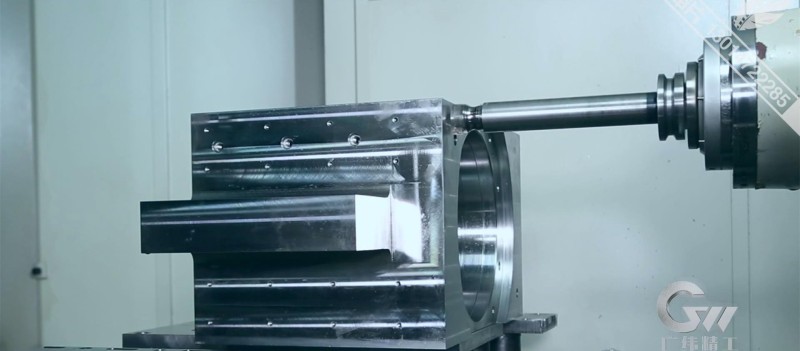

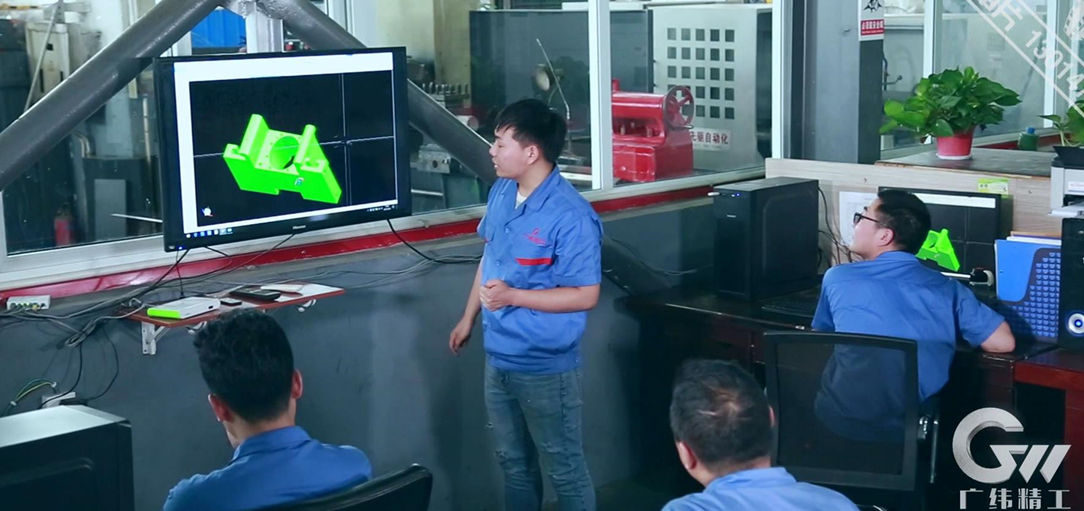

CNC Machining Programming

Programmers use the PC simulation processing to run program, optimizating processing lines and reasonable arranging the processing tools, so that the processing of the workpiece more accurate with neat and beautiful knife lines.

High-Precision Processing Equipment

CNC horizontal machining center, CNC vertical machining center, five axis comprehensive machining center and other high-precision processing equipment ensure the accuracy of Operate Side Intermediate Roller Bearing Block product processing size, also ensure that the complex structure of the workpiece can be smoothly and accurately processed.

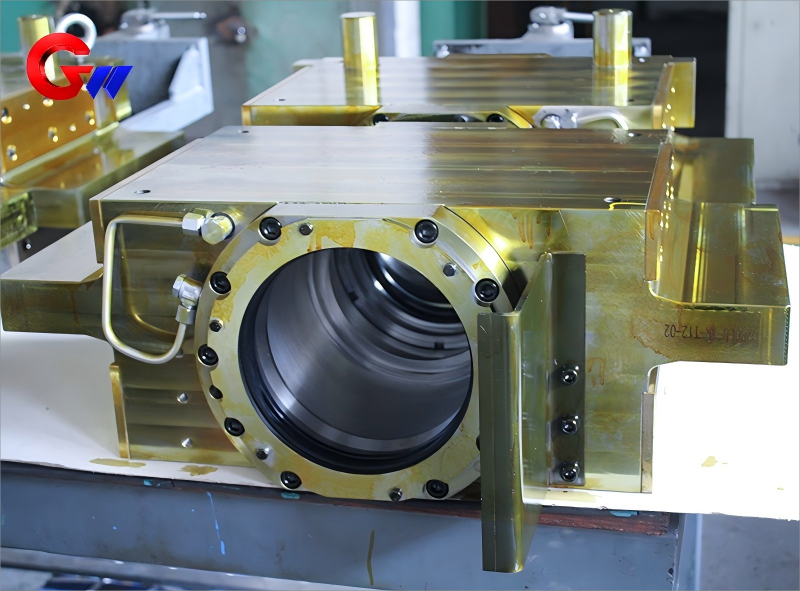

Manufacturing and assembly process of Operate Side Intermediate Roller Bearing Block Processing technology:

CNC boring and milling machine for machining bearing holes (IT6 level accuracy), honing or grinding for final processing.

The positional error of bolt holes is ≤ 0.05mm to ensure precise docking with the frame.

Assembly requirements:

Adjust the pre tightening force of the bearing according to the manufacturer's specifications (such as axial pre tightening force of 8-12kN).

Use hydraulic nuts for installation to avoid impact loads.

Quality Process Control

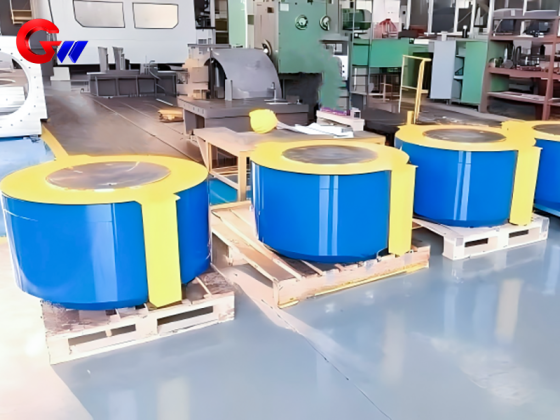

From the processing of blank, flaw detection, heat treatment to the production process, each process has inspectors to check, qualified before the next process processing.

Inspection and Testing

Strict inspection and testing procedures are our quality assurance. Each Operate Side Intermediate Roller Bearing Block has a complete set of chemical composition analysis report, heat treatment report, flaw detection report, dimensional tolerance, shape and position tolerance inspection report (three coordinates and other precision inspection instruments ensure the accuracy of machining size), all of which are traceable and traceable.

Lubrication and sealing of the intermediate roller bearing seat on the operating side of the cold rolling mill

Lubrication system:

Concentrated thin oil lubrication (pressure 0.3-0.5MPa, flow rate 30-50L/min), or oil air lubrication (oil droplet volume 5-10 drops/min).

Lubricating oil viscosity: ISO VG 68-100 (at 40 ℃).

Sealing design:

Combination seal (labyrinth seal+spring reinforced lip seal), dustproof standard ISO 4406 18/16/13.

Sealing material: High temperature resistant fluororubber (FKM) or polyurethane (PU).