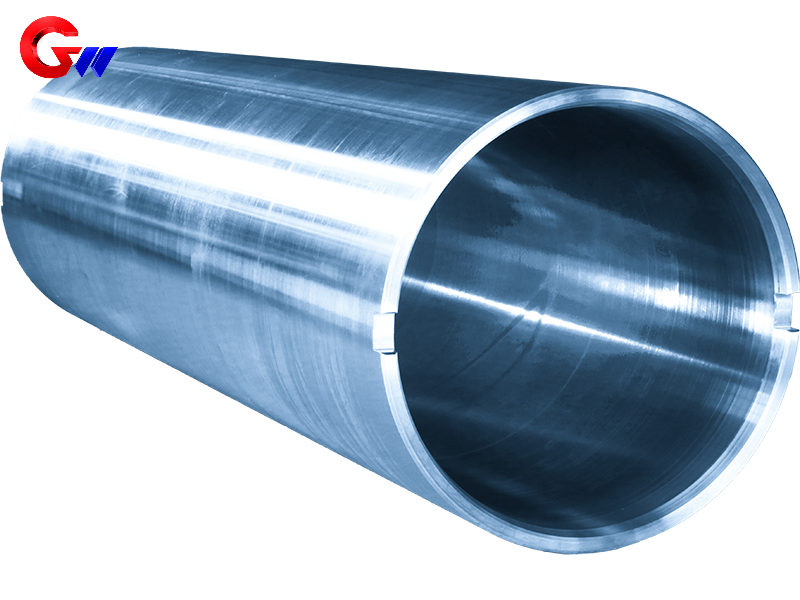

Aluminum foil rolling mill 35CrNiMo steel sleeve (customized)

The 35CrNiMo steel sleeve represents the technological benchmark for high-performance components of aluminum foil rolling mills, and its comprehensive performance is irreplaceable, especially in ultra-thin and high-speed rolling scenarios. However, its value needs to be maximized through refined heat treatment and surface engineering.

- Guangwei Manufacturing Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Aluminum foil rolling mill 35CrNiMo steel sleeve (customized)

| sleeve material | specification |

| 35CrMoV | 665*605*1600 |

Chemical composition of 35CrNiMo (mass percentage)

Execution standards: GB/T 3077-2015 (China), ASTM A434 (American standard)

Range of Element Content (%) Function

Carbon (C) 0.32-0.40 ensures strength and hardness, forming a carbide strengthening phase

Chromium (Cr) 0.60-0.90 improves hardenability, corrosion resistance, and high-temperature strength

Nickel (Ni) 1.40-1.80 significantly improves low-temperature toughness and stabilizes austenite structure

Molybdenum (Mo) 0.15-0.25 suppresses temper brittleness and enhances creep resistance

Manganese (Mn) 0.50-0.80 assists in hardenability and improves thermal processing performance

Silicon (Si) 0.17-0.37 deoxidation to improve strength

Phosphorus (P) ≤ 0.025 impurities (strictly controlled)

Sulfur (S) ≤ 0.025 impurities (affecting thermal brittleness)

Heat treatment process of 35CrNiMo steel sleeve (customized) for aluminum foil rolling mill

Forging: Final forging temperature ≥ 850 ℃, slow cooling after forging (pit cooling or furnace cooling)

Normalization: 880 ± 10 ℃ × 2h, air-cooled

Quenching: 850 ± 10 ℃ oil quenching (cooling rate 80-100 ℃/s)

Cryogenic treatment:- 80 ℃ × 2h (optional, improves dimensional stability)

Tempering: 550 ± 10 ℃ × 4h, water-cooled or oil cooled (to avoid tempering brittleness)

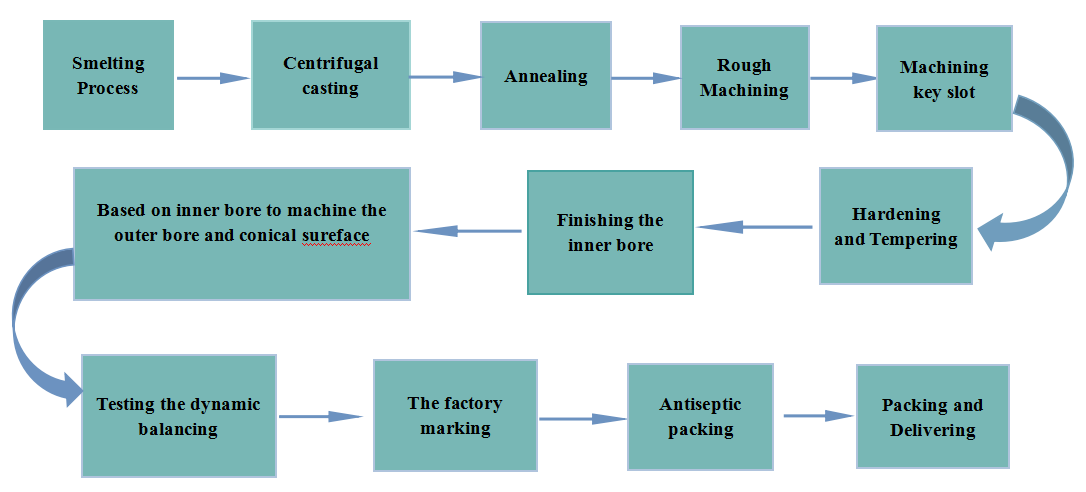

Mechanical processing requirements for customized 35CrNiMo steel sleeve for aluminum foil rolling mill

Dimensional tolerance:

Inner/outer diameter: IT6 grade (≤ 0.02mm)

Cylindricity: ≤ 0.005mm

Surface roughness: Ra ≤ 0.8 μ m (mating surface requires Ra ≤ 0.4 μ m)

Residual stress control: Stress relief annealing (300 ℃ × 4h) is required after machining

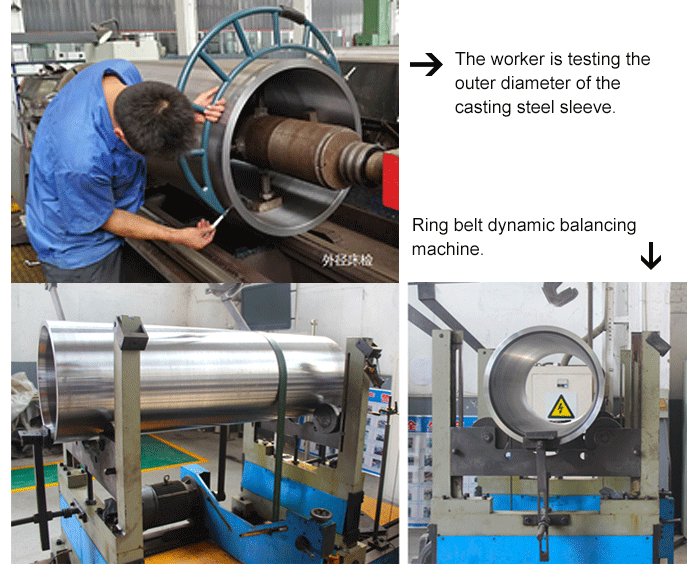

Inspection and testing

Strict inspection and testing procedures are our quality assurance. Each 35CrNiMo steel sleeve has a complete set of chemical composition analysis report, heat treatment report, material mechanical analysis report, dimensional tolerance, shape and position tolerance inspection report, all of which have traceability.

Packaging

We have excellent packaging team and mature packaging technology.

The packaging must ensure the safety of the 35CrNiMo steel sleeve products, so that they will not be lost or damaged during storage, transportation and sale.

Packing ensures product cleanliness. Confirm the cleanliness of steel sleeve product surface before packing.

Our steel sleeve products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

Start your day off right by reaching out to Luoyang Guangwei Precision Manufacturing Technology Ltd. for any casting steel sleeve repair needs you may have.

We have the technology,the eauipment and the knouledge to make sure that you will be 100% satisfied.

Our technicians are extremely experiences and are some of the best in the industry.

Come see how we can save you downtime and keep you up and running.

Time is money,make the call now!

guangwei@gwspool.com or +86-379-64593276