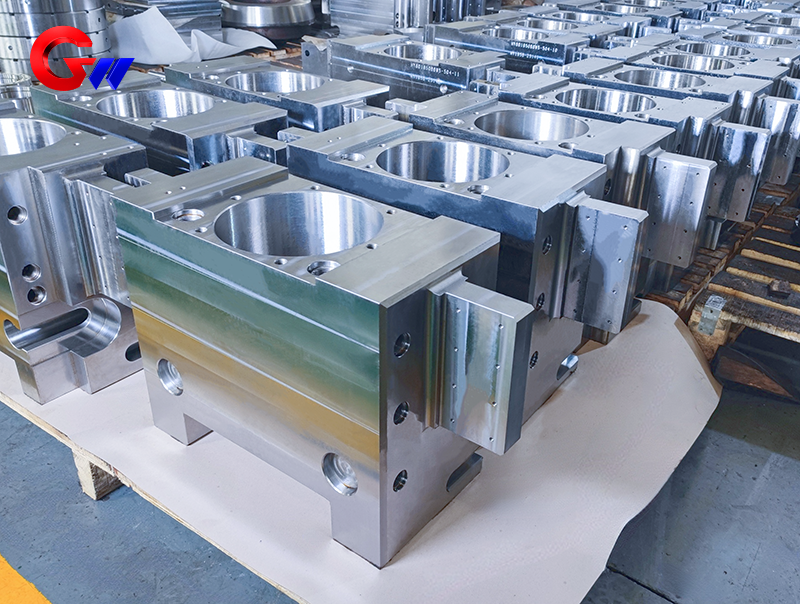

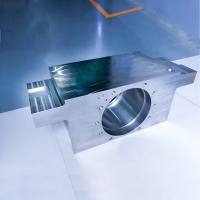

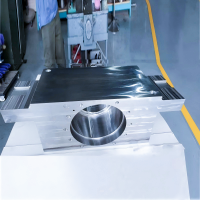

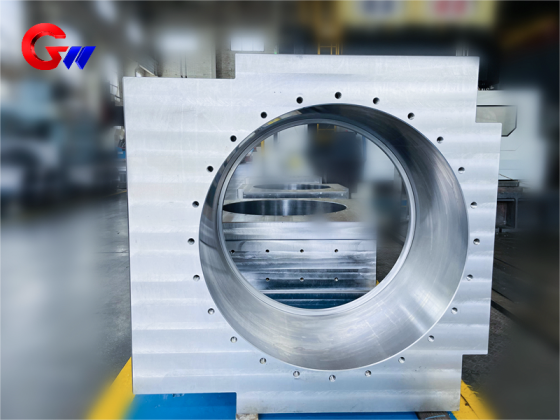

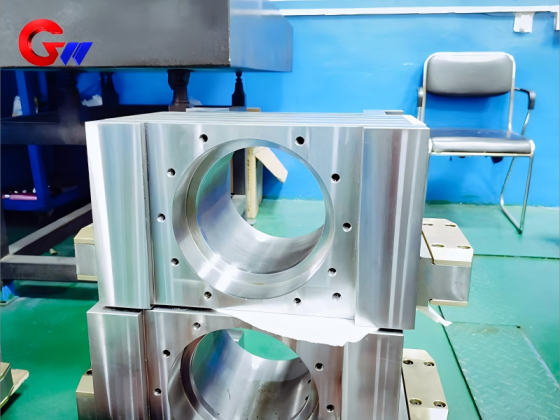

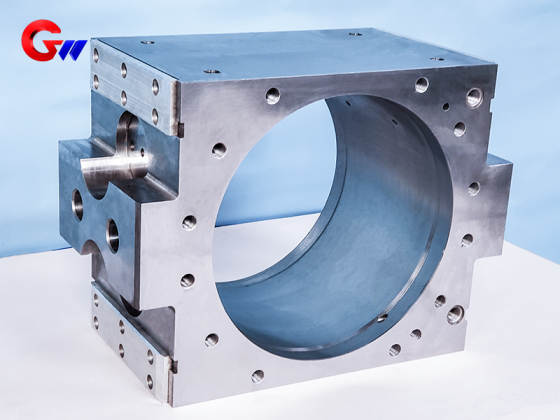

The Casting Steel Bearing Block

In the various components of the mill ,GW Precision casting steel bearing block is an important component of the mill, it has high precision requirements.

Cating steel bearing block Material:

working roll (forgings):45 steel,40Cr,42CrMo

support roll (castings): zg310-570, zg270-500.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Information

Supporting Roller Of The Casting Steel Bearing Block

Typical application scenarios and technical indicators of cast steel bearing block

1. Hot rolling production line (high temperature and heavy load)

Operating condition parameters

Rolling force: 2000-8000 tons

Working temperature: 200-600 ℃ (local peak 800 ℃)

Cooling water pressure: 10-15MPa

Typical lifespan: 3-5 years (rolling capacity of 3-6 million tons)

Representative model

2250mm hot rolling mill (supporting roller bearing seat)

5500mm wide and thick plate rolling mill (work roll bearing seat)

2. Cold rolling production line (high-precision)

Operating condition parameters

Rolling force: 500-3000 tons

Rolling speed: 10-30m/s

Dimensional accuracy requirement: bearing hole roundness ≤ 0.01mm

Typical lifespan: 5-8 years (rolling capacity of 2-4 million tons)

Representative model

Six roll UCM cold rolling mill (middle roll bearing seat)

Twenty roll Sendzimir rolling mill (backing bearing seat)

3. Special rolling mill (extreme environment)

Copper/Aluminum Rolling Mill

Corrosion resistance requirement: pH 3-11 range

Lightweight design: reduces weight by 15-20% compared to steel mills

Stainless steel rolling mill

Anti adhesive steel design: Contact surface hardness ≥ HRC55

Material technical parameters of casting steel bearing block

1. Performance comparison of mainstream materials

Material grade Yield strength (MPa) Impact energy (J) Maximum working temperature (℃) Applicable rolling mill type Cost coefficient

ZG270-500 270 25 350 Light Cold Rolling Mill 1.0

ZG35CrMo 550 40 450 Medium sized Hot Rolling Mill 1.8

ZG42CrMo 650 35 500 heavy-duty hot rolling mill 2.2

ZG06Cr13Ni4Mo 750 60 550 Stainless Steel/Special Rolling Mill 3.5

2. The role of alloying elements

Cr(1.0-1.5%): Improve hardenability and oxidation resistance

Mo(0.2-0.6%): Inhibit high-temperature tempering brittleness

V(0.1-0.3%): Grain refinement (ASTM grade 8 or above)

Ni(4-6%): Improve low-temperature toughness (-40 ℃ impact energy ≥ 40J)

3、 Manufacturing key parameters

1. Casting process parameters

Control standards for key process parameters

Melting medium frequency furnace temperature 1600 ± 20 ℃, oxygen content ≤ 20ppm

Bottom pouring speed of 1.5-2.5kg/s, riser volume ratio of 15-20%

Heat treatment normalizing at 900 ℃ for 4 hours+tempering at 600 ℃ for 6 hours residual stress ≤ 80MPa

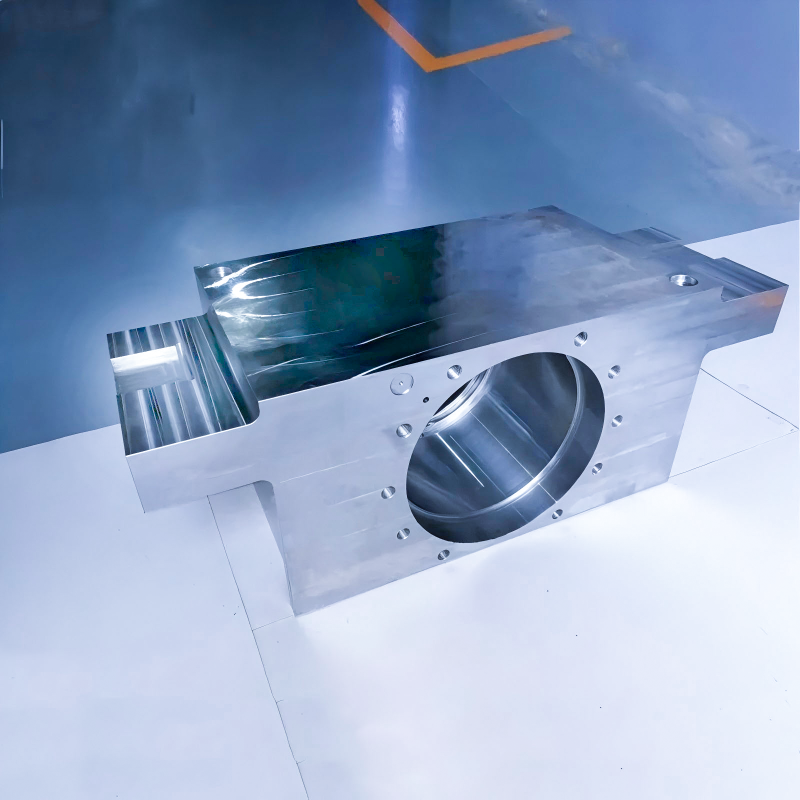

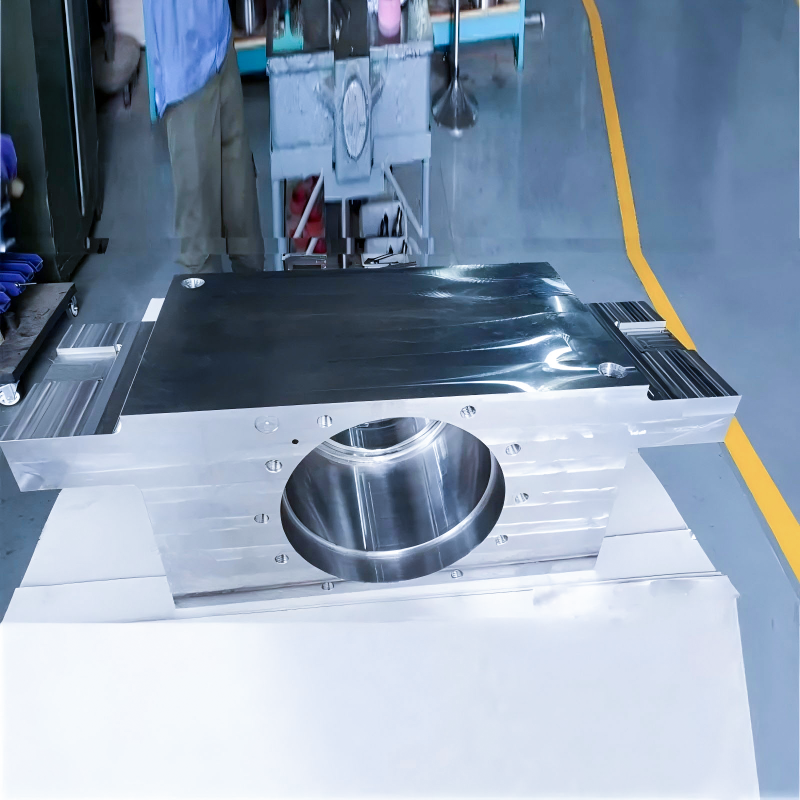

2. Mechanical processing parameters

Processing type equipment/tool accuracy requirements

Bearing hole precision machining CNC boring machine (diamond tool) IT6 level, cylindricity ≤ 0.01mm

Sealing groove machining vertical machining center (CBN blade) symmetry ≤ 0.02mm

Screw hole CNC drilling center (extrusion tap) with 6H level accuracy

3. Surface treatment parameters

Performance improvement effect of processing technology parameters

Ion nitriding at 520 ℃ for 30 hours, ammonia decomposition rate of 30-40%, surface hardness HV900-1000

Laser cladding of Ni60+30% WC with a layer thickness of 0.8mm increases wear resistance by 5 times

Micro shot peening steel shot with a diameter of 0.2mm and a strength of 0.3mA extends fatigue life by 2 times

GW Precision has formed a set of mature mechanical processing technology for the production of casting steel bearing block through the accumulation of long-term experience.

With perfect quality management system and effective after-sales service guarantee, GW Precision casting steel bearing block products won a good reputation.